Bridon Support: Our unique program is tailored to maximize efficiency before, during, and after harvest, providing farmers and dealers with personalized support and peace of mind. From expert guidance and resources to real-time assistance, Bridon Support ensures you’re equipped to optimize your productivity and take your baling to the MAX. Our ultimate goal is to Get You Back to Baling. FAST!

CONTENTS

Helpful Videos

Find out which of our product options best suits your needs.

Properly Install Netwrap (AmericaNet)

Avoid Mistakes: Perfecting Round Baler Adjustments

Twine Troubleshooting

Having issues with your twine? Our experts have solutions for common issues here.

Problem: The knot did not strip off the billhook.

Excessive billhook tension can cause this; decrease tension. Or the billhook may need replacing if it’s rough, worn or bent. Is the knife arm not rubbing the billhook? Adjust or replace it. If the knife arm does not travel far enough, check lobe in cam gear and knife arm roller.

Problem: There’s a simple knot in twine over the bale but no knot in needle twine.

It could be caused by improper twine finger action; adjust to baler manual specifications. Or the needle did not place twine in twine disc, so adjust the needle to specifications and check tensioner at twine box. See if hay dogs are malfunctioning.

Problem: There’s a simple knot in the needle twine.

The twine pulled out of the twine disc. Tighten twine holder and decrease twine box tension.

Problem: The twine breaks at the knot.

Sharp edges may be in the knife arm; smooth the knife arm or replace it. Or you may have too much bale tension; decreasing tension should fix it.

Problem: Twine in the knot is ragged.

The twine holder is too tight, which doesn’t allow the billhook to borrow twine when it rotates. To repair, loosen the twine holder.

Problem: There’s no knot in either twine.

Look for a lost or sheared pin in billhook pinion gear. Inspect the trigger roller and trigger pin. Check that trigger is not bent.

Problem: I’m getting a double bow knot.

This means the billhook tension is too light or that the billhook pinion gear has too much wear. Try tightening billhook tension or replacing billhook pinion gear.

Problem: The twine ends are frayed or uneven.

Your knife is dull. Sharpen or replace it.

Problem: I’m running into other issues.

Is the hay being baled when it’s too green or wet?

How to pinpoint the problem.

When you find yourself at the end of your rope, trip the knotter mechanism and run the tying cycle through slowly. Most of the time the problem can be pinpointed when the tying cycle can be viewed in its entirety.

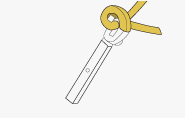

Find Support Staff

-

Jon Schonjon.schon@bridon-usa.com ++563-500-8842Region 10Click for info

-

Giovani PolastroGiovani.polastro@bridon-usa.com ++403-805-8649Region 9Click for info

-

Jerry Greenejerry.greene@bridon-usa.com ++620-491-3640Region 8Click for info

-

Kurt Wearingkurt.wearing@bridon-usa.com +651-328-1097Region 7Click for info

-

Bill Hammerbergbill.hammerberg@bridon-usa.com +816-392-0051Region 6Click for info

-

Alan Patranellaalan.patranella@bridon-usa.com +620-491-3639Region 5Click for info

-

Kory Veringkory.vering@bridon-usa.com +620-491-3644Region 4Click for info

-

Nick Murphynick.murphy@bridon-usa.com +651-492-0684Region 3Click for info

-

Sheri Phillipssheri.phillips@bridon-usa.com +559-285-6482Region 2Click for info

-

Ian Hendryian.hendry@bridon-usa.com +760-550-3770Region 1Click for info

-

For all general inquiriesClick for more

For all general inquiriesClick for more

FIELD TRIAL REQUEST

See Our Products In Action

Field Trial Form

"*" indicates required fields

-

Netwrap FAQ

Can you store net wrap outside?

Please do not store your net wrap outside. Condensation from being outside can lead to water damage inside the packaging resulting in the carboard core expanding or swelling so it will not work on your baler without having to drill out the excess swell.

Do you have black net wrap?

No, that is not a product that we produce. That is an extruded product. All of our netwrap is knitted. We can help with baler adjustments for any customers currently using it that switches to our product.

Do you have long lengths available?

Most labels have long lengths available in various lengths with the exceptions of AmericaNet and Varsity Net.

Do you offer shorter rolls?

No, but our rolls are often up to 12-15 lbs lighter than competitors due to less plastic.

How can a netwrap that is lighter weight be stronger than the heavier weight product I have been using?

Bridon (and our parent company Tama) have spent a lot on research to come up with a product that uses proprietary materials and innovative manufacturing that allows us to make a product that uses less plastic but at the same time gives more strength to the finished product.

How do I know how many wraps of netwrap to put on certain crops?

All of Bridon-USA netwrap products have a graphic showing how many wraps are needed to hold a bale together for certain crops on the netwrap sleeve. For example: Armour Net- 2 wraps are needed for alfalfa, 3 wraps are needed for straw, cereral grains, coastal Bermuda, and wheat hay, and 4 wraps for cornstalks, sudex, haygrazer, and milo stalks.

How many bales can I get out of a roll of netwrap?

The amount of bales depends on the bale size and length of the roll of netwrap. We have a quick reference card that outlines the number of bales per roll.

How many rolls are on a pallet?

48" & 51" netwrap have 16 rolls per pallet. 64" & 67" netwrap have 12 rolls per pallet.

How many wraps do I need to put on a bale?

The amount of wraps depends on the product and the crop being baled. We have our recommended number of wraps on each roll.

How may wraps do I need to put if I am baling peanut hay?

When using Bridon Max netwrap - 4 wraps

I cannot get my net wrap to work right in my baler. How can I fix the problem?

We have Bridon Support, which means we have people in the field who are experts in solving issues. We can come out to your farm, and help you find solutions to your problems. 9 times out of 10 we can find a fix to the issues that you are experiencing- in most cases it is a simple baler adjustment.

What happens if I have an issue with a roll of netwrap?

Each roll of netwrap has a unique identification code inside the tube. Your Territory Manager will work with you to gather information and help resolve the service request.

What is different about the 3 tiers of net wrap?

Magnet or Balekeeper is a very good standard net wrap. Integra series or CNH Legacy is 10% stronger. Bridon Max or Armour net is 10% Stronger than the Integra Series or CNH Legacy product. Bridon Max or Armour net has a different resin, which makes it 10% stronger than Integra or CNH Legacy. This also allows the product to be lighter in weight yet gives you the strength you need.

When using netwrap, where does the actually strength come from to hold the bale together?

Netwrap has vertical strands called Franze’s and and the zig zag strands are called the Schuss’s. All the strength of netwrap is in the Franze. In fact you can cut the schuss out of the netwrap and the bale will still hold together. This is important to understand because some netwrap manufacturers will add plastic to the schuss by making an “X” out of it or doubling the schuss to say it is stronger. This is false, the only job of the schuss is to space out the franzes. This added plastic can cause ridges in the rolls and uneven feeding in some balers.

Which colors does your netwrap come in?

We offer both white and green netwrap for most items. There are a few skus that are only available in white.

Why would I use the top tier product that cost more than the other 2 tiers?

Depending on your operation and what your goals are, Bridon Max and Armour Net allows you to put on the least amount of wraps while maintaining strength. This allows you to have the least amount of plastic on the farm, and is more cost effective per bale.

-

Twine FAQ

Are all baler twines the same?

No, there can be many differences from one manufacturer to another, based on many factors. Even within Bridon, we manufacture many different types of twines, with different specifications, for each application. Contact our experts for more information.

Are there other materials that manufactures use to produce twine?

Yes, some twine manufacturers use other plastics and additives that typically degrade the performance of the twine, either while being used in a baler or while bales are being stored. To ensure you’re using the best quality twines, choose Bridon, a manufacturer you can trust, with a history of quality baler twines.

Can I store twine outside?

Yes, Bridon twine can be stored outside. We use higher than average amounts of UV stabilizer to protect the twine from UV degradation. Although, for long-term storage, we recommend storing all agricultural plastics inside, whenever possible. Protecting your investment will pay off in the long run.

Can used baler twine be recycled?

Yes! Baler twine can be recycled and reintegrated back into baler twines for reuse. The process involves collection from the farm, sorting, cleaning, shredding/ grinding, extrusion/ pelletizing, prior to reuse. The resulting resin then becomes what’s known as “Post Consumer (Recycled) Resin” or “PCR”. We are involved in nearly all aspects of this process in an effort to better utilize our resources.

How can I participate in recycling my used twine?

There are national and local collection schemes throughout North America, which aid in the collection and transportation of used agricultural plastics, including baler twine. For more information, please contact your local Bridon representative. Also, be sure to separate your different types of plastics, to help us in the sorting process.

How does Bridon twine compare to my current twine?

Bridon twines are manufactured using the most advanced equipment and techniques, with higher specification resins, which create strong twine without excess thickness. This means Bridon twine is less bulky than a traditional twine of equivalent strength, which enables more stable and secure knots. Bridon Max twines are overbuilt for higher performance in the field, to get you back to baling fast. For help in choosing the right twine for your application, please feel free to contact your nearest Bridon USA representative.

How should I connect the spools in the twine box?

Each operator has their preferred type of knot. The most ideal knot should be compact and easily pass through the guides and tensioners, without coming un-tied. In addition, make sure the twines are routed properly within the baler, per the manufacturer's instructions provided with the baler. A few common knots for connecting spools may be square knots or reef knots, surgeon’s knots or fisherman’s knots, among others. For further assistance in tying proper knots, please contact your local Bridon Support professional.

Is twine color important and does it affect performance?

The color of the twine has no impact on the strength or knotting performance. Many advancements in raw material and color pigment carriers have reduced the differences in how different colors perform in a baler. Not all manufacturers use high quality color additives, and resins but with Bridon, you know what to expect; consistency and reliability.

Is your Twine tested in all balers and on all knotters?

Yes, Bridon R&D works closely with all OEM’s (Original Equipment Manufacturers) engineering departments to test, validate and approve the use of the right twines for each application, taking the guesswork out of the equation, when using Bridon Twines.

Should twine packs and spools be handled carefully?

Yes, careful handling of the spools will ensure that the twine will perform properly in the baler. If damaged spools are used in a baler, they may cause tying problems and damage to some components in the tying system.

What happens to the used twine that isn’t recycled back into twine?

Within Bridon, we incorporate additional PCR polypropylene into other products such as netwrap cradles, end bungs, carrying handles and other packaging components. In addition, the excess PCR material helps to reduce the plastic impact within the automotive and construction industries in what’s called an open loop process.

What is fibrillation?

Fibrillation is the name to describe the fine mesh-like appearance of the twine when un-twisted. It is a part of the production process designed to make twine softer and more flexible to assist with tighter knot formation & knot holding capability. Quality fibrillation allows the twine to perform seamlessly in the tying system of the baler.

What is the difference between Bridon Max and Black Gold?

Bridon Max is give you a minimum knot strength and Black Gold gives you an average knot strength.

What is the difference between tensile strength and knot strength?

Tensile strength is the maximum breaking force of a specific twine, without a knot, when measured while being pulled between two opposing drums. Knot strength describes the maximum measured strength a twine containing a knot can achieve, before breaking while being pulled between two opposing drums.

What is the main ingredient used to manufacture baler twine?

Bridon twines contain nearly 100% high quality polypropylene, combined with color pigment, proprietary additives and UV stabilizers. We only use the highest quality resins and additives to provide premium mechanical properties & workability in the field.

Which direction should twine unwind from a spool?

The twine should unwind from the center of the spool in a counterclockwise direction. If the twine unwinds in a clockwise direction, the spool and/ or the label is upside-down.

Why should I switch from sisal twine to plastic twine?

Sisal is a naturally made product so it has inconsistencies (thin spots) whereas plastic twine gives you consistency in size and strength.

Will all Bridon Twine spools fit in my baler?

Standard Bridon twines are manufactured to be able to fit in common balers with smaller twine boxes. Bridon Endurance extended length spools offer many more feet per spool but are intended for modern balers with larger twine boxes.

Will I need to adjust my baler to use Bridon twine?

Like all makes of twine, some balers may require slight adjustment to obtain the best knotting performance between different twine types and producers. For further assistance, please contact your Bridon Support professionals. Bridon twines provide peak performance with all makes and models of large square balers, when matched to the correct application, in a properly adjusted and maintained baler.

Are Bridon Impax Technology twines expensive?

Since Impax technology twines contain up to 40% more twine in every spool, compared to standard twines, the cost per spool or cost per pound may seem relatively expensive. But don’t forget that each spool or each pound of twine can actually make many more bales than standard twines. This is where calculating the cost per 1,000’ feet or cost per square bale is key, to make a fair comparison. If you need assistance, please contact one of our Bridon Support experts and we’ll be happy to help.

Are there any advancements in twine technology?

Yes! Bridon is proud to introduce Bridon Max Twine with Impax Technology inside! This revolutionary & patented technology combines a smaller twine diameter with unique shock absorbing characteristics, which protects the knots from breaking, improves knotting performance and increases efficiency, all while reducing the amount of plastic needed for the season.

Are there any other manufacturers who produce twines like Bridon’s Impax Technology?

No. Like many of Bridon’s innovative products, other manufacturers try to replicate the cutting-edge products that Bridon produces, but they are unable to achieve a similar end result in their products. Genuine Bridon Impax Technology is the only advanced twine on the market that increases efficiency and productivity to a whole new level.

Can I increase my bale weights using Bridon Impax Technology twines?

In many cases, operators can increase their efficiency by making heavier bales using Bridon Impax Technology twines. Heavier bales reduce the amount of twine consumed during a season, reduce transportation costs and reduce the amount of storage needed to protect the same amount of crop. Please contact your local Bridon expert to learn more about how we can help you make heavier bales and increase your overall efficiency.

Can I recycle Impax Technology twine?

Absolutely. All Bridon twines, including Impax twines are 100% recyclable and it’s our goal to be an active participant in doing our part to close the loop.

How long has Impax Technology twines been in development?

Before Bridon introduces any new product to the market, we invest many years & thousands of hours in the field to perfect the product for our end users to be proud to use our products. Impax Technology is no different. After over 6 years of development and millions of bales made all over the globe, we are confident that Bridon Max Impax Technology can improve nearly any operation.

How many bales can I make with a full baler load of Impax technology twines?

The short answer: Many more bales! If we look at one example: We produce our standard Bridon Max 4,000’/ 550, which would make approximately 895 (3X4X8’) bales. If the Bridon Max with Impax Technology 5,300’/ 500 spools were used, an operator could make approximately 1,180 bales per baler load. That’s an increase of 285 more bales in every baler load of Bridon Impax Twine!

Is the twine rebate available for all twine?

No, currently the rebate is $50 per pallet in the US and $75 per pallet for our new Bridon Max with IMPAX Technology twine and only payable on full pallet quantities.

What if I don’t want to make heavier bales with Impax Technology?

You don’t have to! We now have a full range of heavy twines with Bridon Impax Technology. Choose the right twine for your application and goals and experience all the benefits that Impax provides to your operation. This includes; Many more bales per twine box load, more time tin the cab of the tractor, less time loading spools in the twine box, less misties and broken bales and less downtime.

What kind of twines are available with Impax Technology?

Bridon Impax Technology was first developed for high density large square balers, since the twine was becoming increasingly thick to hold denser bales together, we found a new way to combine strength, while providing a smaller diameter twine. We now offer multiple types of heavy twines with Impax Technology – from medium twines to standard density & ultra-high density large square bales, we’ve got you covered.

Why should I use Bridon Impax Technology twines?

Bridon Impax Technology twines provide noticeable advantages to any Large Square Baling operation. Due to the twine’s reduced diameter, we can provide many more feet per spool, which increases the number of bales an operator can make with each baler load of twine. The smaller diameter of the twine also reduces common tying issues experienced in the field, while reducing the wear and tear on the tying system components in the baler. Couple this with a large reduction in the amount of plastic used per bale or per season, you are helping to reduce your carbon footprint in your own operation.

-

BRIDON Support FAQ

Does Bridon USA offer other products besides Netwrap and Twine?

Bridon-Usa offers a Full Line of Crop Packaging Products including Grain and Silage Bags, Silage Wrap, Bunker Covers, Hay Tarps, sisal twine, and preservative options that fit your operation.

How many square bales will a spool make?

Calculate the amount of twine needed per bale. Bale length (X2) + bale height (X2) x number of knotters (2, 3, 4, 5, 6 or 8 knotters depending on baler) = total amount of twine used per bale. Example: Bale Length: 96 inches Bale Height: 36 inches # of Knotters: 6 ((96in X 2) + (36in X 2)) X 6/ 12in = 132 feet of twine needed per bale. We also recommend adding some additional length for the twine needed for each knot on the bale. (~2 feet additional length for a double knotter; ~1 foot additional length for a single knotter, per bale) 132 feet of twine per bale + 2 feet additional length for knots in a double knotter baler = 134 feet of twine needed per bale. Bridon USA guarantees the stated length of the spools & bales of twine, for your peace of mind during your buying decisions. Estimate the number of spools needed: Length per spool: 4,800 feet Length of twine needed per bale: /134 feet per bale # of square bales per spool = 35 square bales per spool Remember, in a double tie large square baler tying system, an upper and lower twine are needed for each knotter and may create some variances in total bale counts per baler load of twine. Using the number of bales per spool provides an estimate of the total possible number of bales with a full twine box of Bridon Twine.

I have talked with one of your Bridon Support technicians and they are talking about making adjustments to my baler. I don’t have time for that. I just want to bale.

Varying field conditions, weather and crop conditions can lead to the need to make some adjustments to your baler to make the baler and the netwrap work perfectly together. Just as you most likely would not wear the same clothes when baling corn stalks in October vs baling hay in July your baler may need some small adjustments to run correctly.

What can Bridon Support really help me with? I do all of my own repairs and fixing.

Our Technical Managers have a total of nearly 100 years of experience in the field and technical aspects of the balers. Since we cover such a large area we see many different “issues” that we can bring that experience to help you.

What is the difference between cost/pound, cost/bale and cost per 1,000 feet?

Cost per pound only considers the weight of plastic within a spool of twine but does not factor in the density or runnage of the twine, which can vary greatly from one manufacturer to another. This comparison can only be used if the two twines being compared are of identical runnage. Cost per square bale, based on an average bale length, compares an equal amount of twine needed to make one square bale and the associated cost of twine for each bale. Increasing average bale density can also help to reduce the twine cost per season of any given operation. Cost per 1,000 feet compares an equal length of twine, regardless of the density or runnage of the twine, for an equal length comparison.

Where can I buy your twine or netwrap?

I need to know where you are located in order to find a dealer near you. We have several distribution channels, and in most cases we have a dealer near you. If you have a Case or New Holland dealer near you- our products are in their labels, which are Balekeeper, Case or New Holland, or Armour Net.